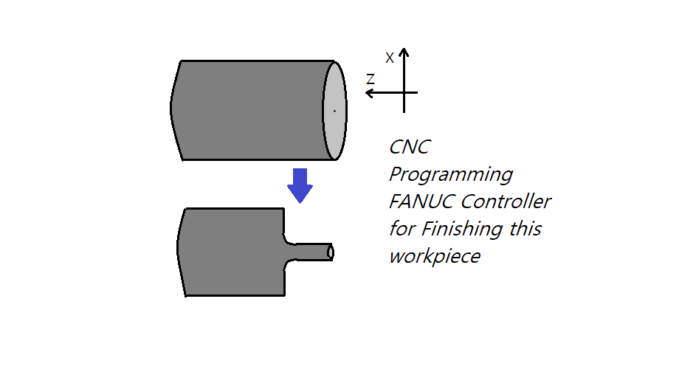

This article describes about the CNC Programming for machining the following raw material

The program will be as follows :

N10 G50 S2000 T04

N15 G96 S200 M03

N20 G00 X12.0 Z1.0

N25 G01 X5.0 Z-10 F0.2

N30 G00 X5.0 Z1.0

N35 G01 X2.0 Z-5.0 F0.2

N40 G00 X6.0 Z0

N45 G02 X5.0 Z-10 R3

N50 G00 X20 Z20

N55 M30

Explanation :

Watch Full YT Video Explantion

N10 – G50 means scaling function off, this will switch off any zoom in or zoom out case. S2000 will start to rotate the spindle at RPM of 2000. T04 will select the tool number 4.

N15 – M03 will rotate the spindle in clockwise direction.

N20 – G00 means rapid positioning, the tool will quickly move to the given co-ordinates which is just above the edge of workpiece in this case.

N25 – G01 stands for linear interpolation, this will instruct the tool to cut the workpiece till the given co-ordinates linearly step by step with the given depth of cut ( 0.2mm ) in this case.

N45 – G02 will instruct the tool to cut in circular way clockwise direction with the given feed rate.

M30 stans for end of the program.

Read more: G and M codes