Limits, Fits and Tolerance :

These three words are one of the most confusing words in terms of their definition. One is linked to the other. In all sorts of interview related to Mechanical these words are often asked for. Read this article completely and you will get a clear idea of what are the definitions and differences among these words.

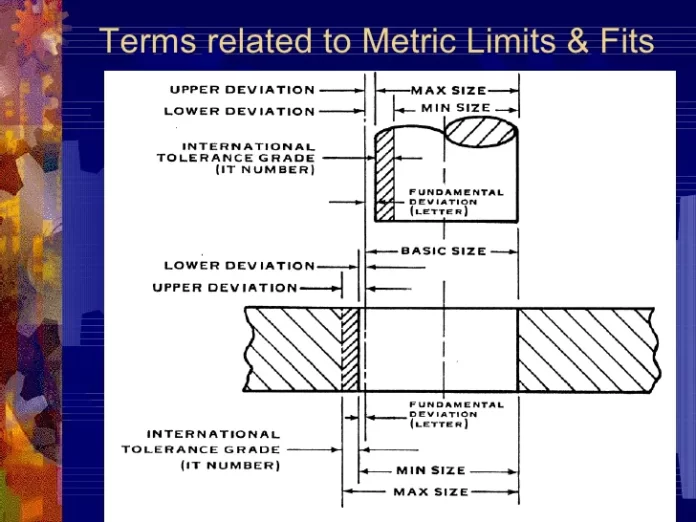

Limits –

It is the two extreme permissible size from the basic size in between which the job has to be manufactured or dimensions has to maintained

Limits are of two types

1. Upper Limit

2. Lower Limit

Ex – If the given dimension of a shaft is 40 ±0.05mm, then the upper limit is 40.05mm and the lower limit is 39.95mm.

Fits –

Degree of looseness or tightness between 2 mating parts is known as fits.

Fits are of 3 types:

Clearance – When hole size is bigger than shaft size

Transition – It is the most commonly used fit.

Interference – When shaft size is bigger than hole size

Tolerance –

The difference of the basic size from the upper limit/lower limit gives the tolerance.

Tolerance are of two types:

1. Bilateral ( Ex- ±0.05mm )

2. Unilateral ( only + or – )