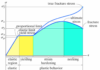

Heat Treatment – A combination of operation involving heating and cooling under controlled conditions for obtaining desired properties in a material.

Heat Treatment also infulences creep resistance of steel. At temperature of 500 degree Celcius or above the max cree resistance is usually produced by normalizing, provided drawing temp. is about 100 degree more than the test temperature

The lowest creep resistance is produced by quenching and drawing. The creep resistance of steel in anealing conditions is between the resistance for the other two treatments.

Important Heat Treatment Processes :

1. Normalizing

2. Annealing

3. Hardening

4. Tempering

5. Precipitation

6. Spherodizing

Effects of Heat Treatment :

One or more of the following effects are obtainable with the help of various heat treatment processes :

1. Change in microstructure of metal

2. Softening of metal improving machinability (Annealing)

3. Removal of gases from metal cutting

4. Relieving of internal stresses set up by cold working and restoring ductility ( Annealing or Normalizing )

5. Restoring electrical conductivity of a cold worked material ( Annealing )

6. Increasing hardness with strength

7. Improving the magnetization properties of steel for producing permanent magnet. (Hardening and Tempering )

8. Removing some of brittleness caused by steel hardening process and improve toughness.

9. Refining grain structure after hot working which cause distortion in the grain structure of the metal. (Normalizing and Annealing )

10. Producing a hard wear resisting surface on a tough core of a steel piece. (Case Hardening ).

11. Softening and Toughening of high carbon steel. (Spherodizing )

12. Removing the effects of previous heat treatment process. (Normalizing)