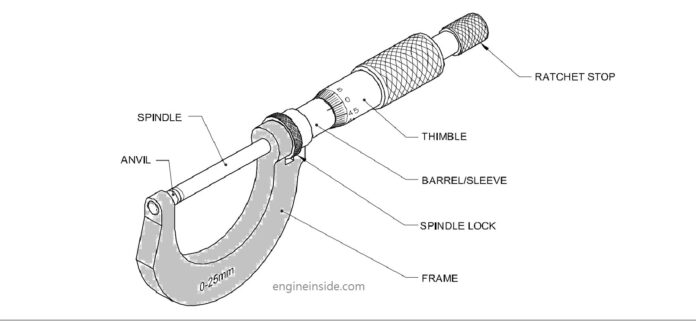

Micrometer Introduction :

Micrometer is a popular measuring instrument widely used to measure outside dial and other dimensions

- Micrometer Reading = Main Scale Reading + Thimble Scale Reading

- Uses of Micrometer – To measure outside dia and dimensions

- Mechanism – Nut and Screw

- Material used –

Anvil and Spindle are made of Stainless Steel

Frame is made of Cast Iron

Tip of the anvil and spindle is made of Tungten Carbide

Rest of the instrument is made of Invar Steel

Specifications of micrometer available :

Range – 0-25mm, 25-50mm and so on.

L.C. Calculation

Least Count (L.C.) = 0.01mm

=> L.C. = (One Main Scale Division)/(Total Subscale Division)

= 0.5/50

= 0.01mm

Another Method of L.C. Calculation

Lead/Total Thimble Division

0.5/50 = 0.01mm

Method of Reading = Main Scale Reading + (Thimble Scale Reading x L.C.)

Other types of Micrometer ;

- Blade Micrometer : Used for measuring outside circular formed tool’s diameter and depth of all types of narrow grooves, slots, key slots etc.

- Screw Thread Micrometer : Used for mesuring Pitch Dia of threads

- Tube Micrometer :Used for measuring wall thickness of tubing and other parts with cylindrical walls.

- Two pin Inside Micrometer : Used for Internal dia measuring, slot measuring and others. Mechanism is Nut and Screw, the pins are made of tungsten carbide, remaining part of Invar Steel and the Least Count is – 0.01mm.

- Three pin inside Micrometer : Same mechanism i.e. nut and screw. Least Count is 0.005mm, since total thimble scale divisions are 100.

Read more about