Some important questions for interview in CNC Machining/Production.

https://youtu.be/YalZO1SyzEg

Also Read : CNC Programming

Two Questions regarding quadrilaterals which includes concept of Rhombus and mid-point theorem.

Also read : Pythagoras Theorem with proof

What about those Power Feeds?

There are two approaches. First of all, CNC's have the ability to jog. Jogging is where

you're spinning a simulated electronic handwheel, or holding down a button or joystick

to make the axis move. You generally select an axis, select a speed or multiplier (x1,

x5, x100 or whatever), and then operate the control to move the axis.Here...

Applications/Uses of IC Engines

Road Vehicles (Scooters, Motocycles, Buses)

Aircraft

Locomotives

Pumping Sets

Cinemas

Hospital

Other Industrial Applications

Two Stroke Petrol Engines ;

50cc engines develops max brake power of 15 kw at 5000 rpm and is used in mopeds.

The 100cc engine develops brake power of 3kw at 5000 rpm is used in scooters.

The 250cc develops max power...

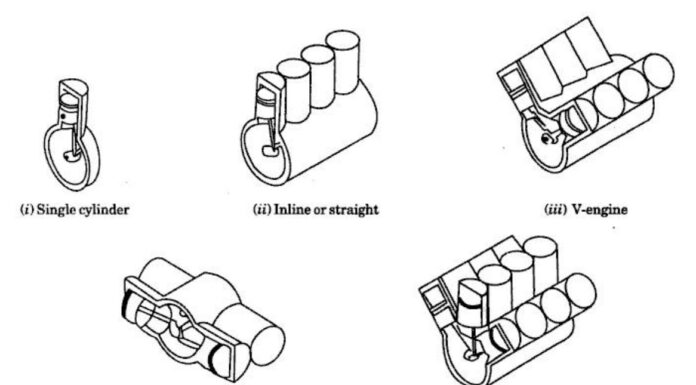

Classification of IC Engines :

According to cycle of operation;

Two Stroke cycle engines

Four Stroke Cycle engines

According to cycle of combustion;

Otto Cycle (Combustion at constant volume)

Diesel Cycle (Combustion at constant pressure)

Dual Combustion or SemiDiesel cycle engine (Combustion partly at constant volume and partly at constant pressure)

According to valve arrangement :

Over Head Valve engine

L-Head Type engine

F-Head type engine

T-Head type...

Entropy

Entropy is a function of a quantity of heat which shows the possibility of conversion of that heat into work. The increase in entropy is small when heat is added at a high temperature and is greater when heat is added at a lower temperature. Hence for maximum entropy, there is minimum availability for conversion into work and for...

Q.1) Which among the NC operations given below are continuous path operations?

Arc Welding (AW) Milling (M)

Drilling (D) Punching is Sheet Metal (P)

Laser Cutting of Sheet Metal (LC) Spot Welding (SW)

A) AW, LC and M (b) AW, D, LC and M

(c) D, LC, P and SW (d) D, LC, and SW

Correct Option - A

Q.2) High speed steel tools retain their...

Braking system

Brakes are employed to stop or slow down the speed of a vehicle.

When brakes are applied to the wheels braking force is created which opposes the speed of the wheel or rotation of the wheels.

Braking requirements :

The vehicle must stop in the smallest distance

It must act suddenly in emergency.

It must have strong braking...

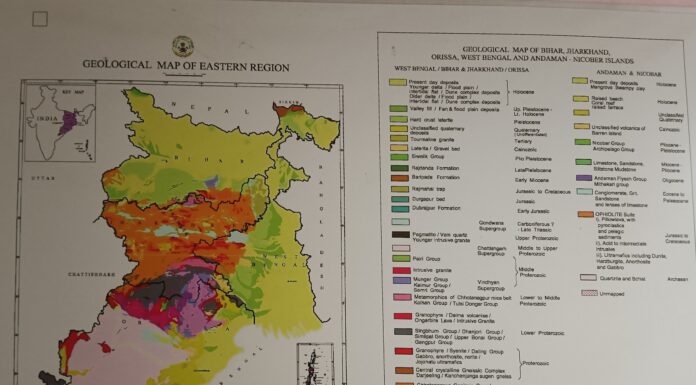

This Geological map shows details of geological belts in Eastern India. It covers details of Bihar, Jharkhand, West Bengal, Orissa and Andaman & Nicobar Islands.

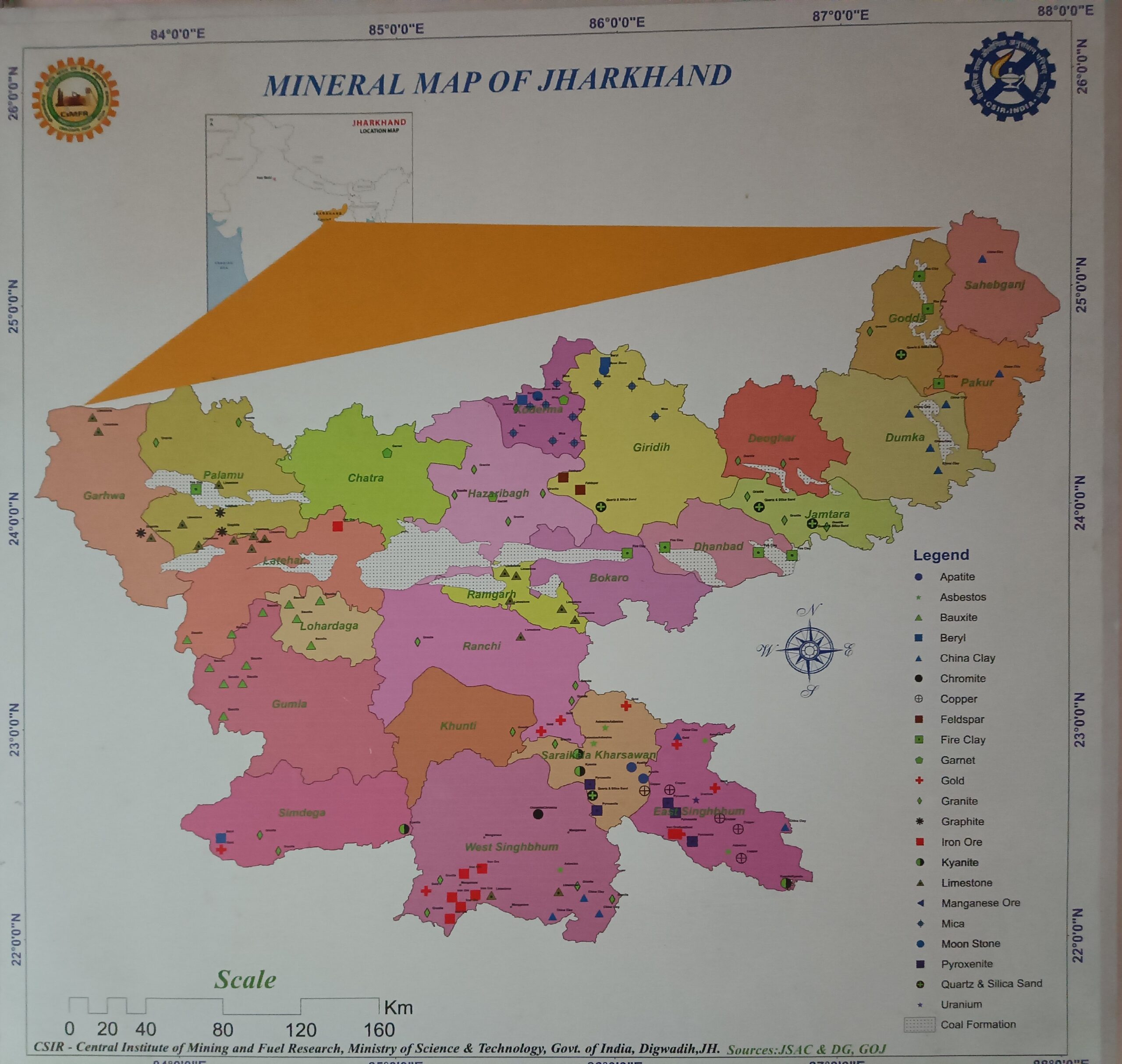

The mineral map shows concentration of different minerals in different areas with different symbols all over Jharkhand.