ALLOYS OF NICKEL

(i) German silver. It is a cupro nickel to which zinc has been added. A typical composition is 60% copper, 30% nickel and 10% zinc. Addition of zinc brings down the cost. Its colour is silvery with a slight pale tinge. It is very ductile and malleable and corrosion resistant. It is used for making electrical contacts,...

Non Ferrous Metals and Alloys - Properties and Uses :

Non-ferrous metals and alloys do not contain any significant quantity of iron. The most common non ferrous metals used in engineering applications are copper, aluminium, tin, lead and zinc. Nickel, magnesium and antimony are also used for alloying the aforesaid non-ferrous metals.

Copper.

Copper is a corrosion resistant metal of an attractive...

Bronze ;

Bronze is an alloy of copper and tin however commercial bronzes may contain other elements besides tin. In fact, alloys of copper with aluminium, silicon and beryllium, which may contain no tin are also known as bronzes. This article describes about different types of Bronze and their practical applications.

Tin bronzes are of a beautiful golden colour. As in...

CNC Machines have these advantages :

High Repeatability and Precision e.g. Aircraft parts.

Volume of production in CNC is very high

Complex contours/surfaces need to be machined. E.g.

Turbines

Flexibility in job change, automatic tool settings, less

scrap

More safe, higher productivity, better quality

Less paper work, faster prototype production, reduction

in lead times.

Disadvantages :

Costly setup, skilled operators are always needed.

...

NC - Numeric Controlled and CNC - Computer Numeric Controlled Machines differ in these ways :

The difference between NC and CNC is one of age and

capability. NC is older compared to CNC

The earliest NC machines performed limited functions

and movements controlled by punched tape or punch

cards.

As the technology evolved, the machines were equipped

with increasingly powerful microprocessors (computers)

with...

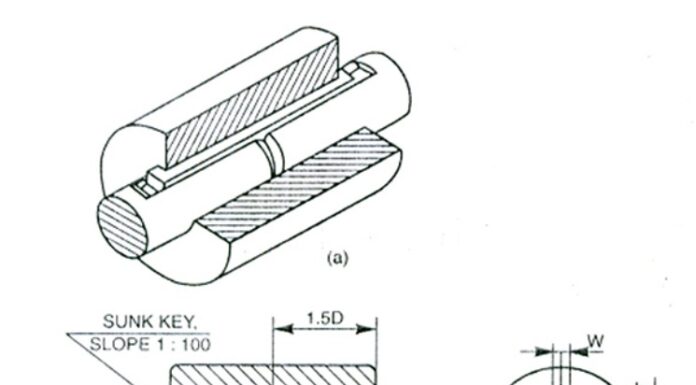

Couplings:

Shaft couplings are used for connecting two shafts end for transmitting rotary motion directly from one shaft to another. They act as a one unit and transmit power. The classification of shaft coupling is as below:

A. Rigid couplings

B. Flexible couplings and

C. Loose couplings

(A) Rigid Coupling:

It does not permit any relative rotation between the two shafts i.e two coupled...

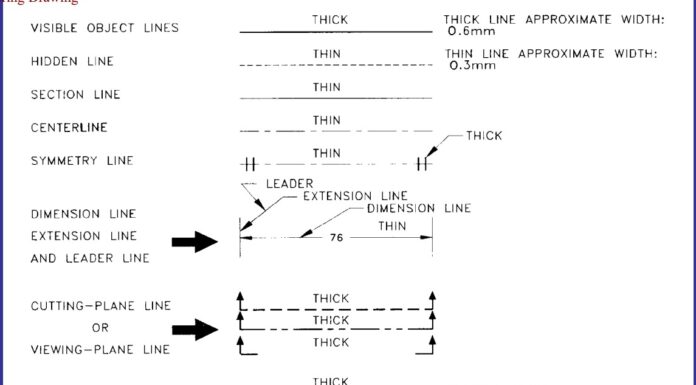

What is Engineering Drawing ?

Engineering Drawing is a language to express details of any particular machine part, tool, process of working or assembling and others. Various symbols are used in E.D. to represent factors like- surface roughness, cylindricity, tolerance, diameter, max or min material conditions and other things.

In modern age Engineering Drawing has been replaced by Softwares like Auto...

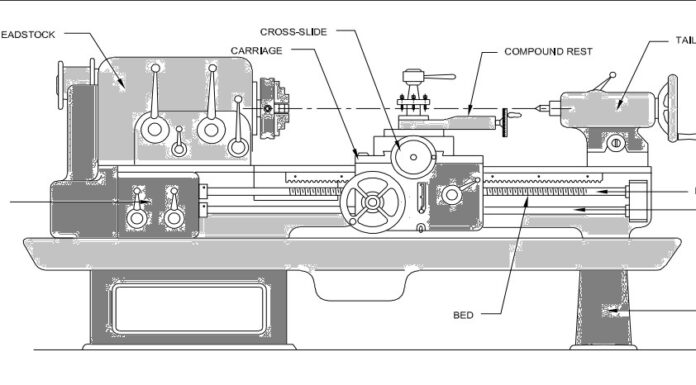

The main parts of a Lathe Machine are :

- Headstock

- Tailstock

- Carriage

- Cross-slide

- Compound slide

- Bed

- Quick change gearbox

- Legs

- Feed shaft

- Lead screw

The following figure shows the parts of lathe in details ;

Specifications of Lathe Machine :

The maximum diameter of a work that can be held.

The swing over bed. This is the perpendicular distance from the...

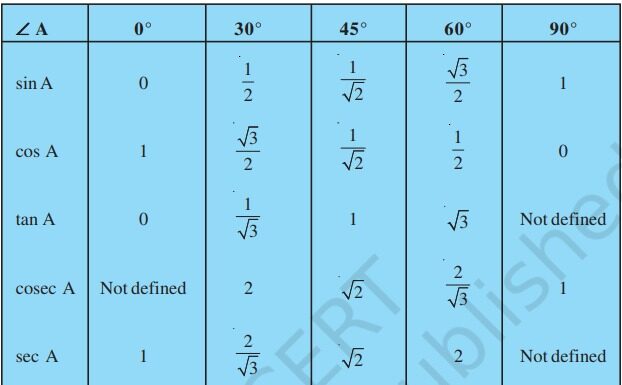

These are most commonly used trigonometric ratios ;

Also, these relations need to be remembered,

sin (90° – A) = cos A, cos (90° – A) = sin A,

tan (90° – A) = cot A, cot (90° – A) = tan A,

sec (90° – A) = cosec A, cosec (90° – A) = sec A

Arithmetic Progression ( AP ).

An arithmetic progression is a list of numbers in which each term is

obtained by adding a fixed number to the preceding term except the first

term.

This fixed number is called the common difference of the AP. Remember that

it can be positive, negative or zero.

Examples :

(i) 1, 2, 3, 4, . . .

(ii) 100, 70, 40, 10,...