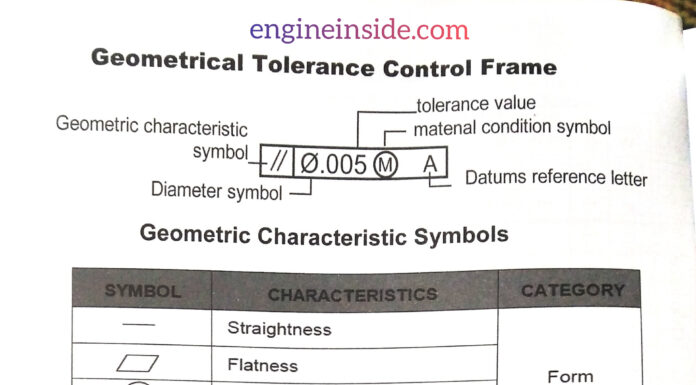

Geometric Tolerance control frame and Commonly used Symbols

The picture shows Geometric Tolerance control frame used in Engineering drawing/Drafting Auto Cad. It also shows commonly used symbols used in the drawing. Refer the image for clear understanding.

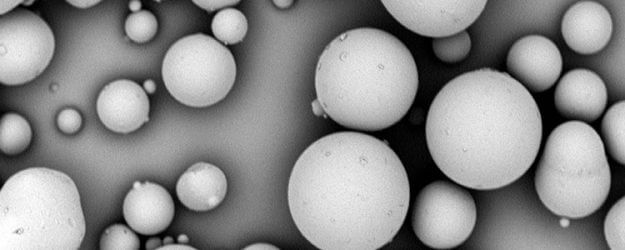

Spheroidizing ;

The heat treatment process which produces globular form of carbide in steel is known as Spheroidizing.

Purpose ;

To soften high carbon steel to increase the machinability.

Process :

Any process of heating and cooling that produces a round or globular form of carbide in Steel is called Spheroidizing. One of such process involves heating and cooling of steel alternatively at...

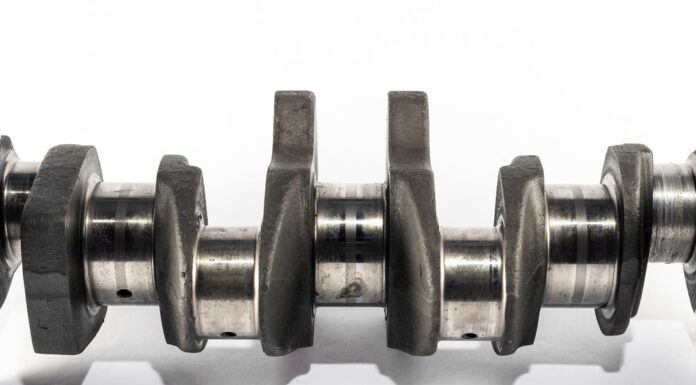

Maraging Steel :-

1. Maraging Steel find applications as aluminum die casting dies, inserts, extrusion dies, forging dies, punches, cold hardening dies and dies holder.

2. Maraging Steel are low carbon, high nickel alloy steel , capable of attaining yield strength in excess of 185 MN/M2 in combination with wood fracture toughness.

Composition of Maraging Steel :

This Steel contain :

Carbon C...

Tempering -

The process of reheating hardened steel to some temp. below its critical range in order to decrease hardness and impart toughness is known as tempering.

Purpose :

1. To impart toughness to an already hardened steel.

2. To improve yeild point of structure steel which have already been hardened by Quenching.

Process :

1. Heating the hardened steel to a desired...

Lower Critical Temperature

All Steel being heated at a uniform rate from room temperature show a comparatively much slow rise in temperature on reaching a temperature about 723 deg. Celsius. This temperature at which a check or arrest in rise of temperature appears in Steel at uniform rate of heating is called Lower Critical Temperature. This temperature has the same...

High Speed Steel HSS :-

HSS removes metal at a much higher rate or speed than ordinary carbon Steel.

HSS are categorized by being heat treatable to very high hardness (64 HRC) and of retaining their hardness and cutting ability at temp. as high as 540 deg Celsius. Thus permitting truly high speed machining.

Above 540 deg c. they rapidly soften and...

Normalizing ;

1. Refines most part of the steel.

2. To remove internal stresses.

3. Reduce brittleness caused by cold working.

4. Restore toughness of metal reduced by prolonged hot working.

5. To obtain finer grain structure and relatively higher value of yield point and impact strength.

Process :-

Heating plain carbon steel above upper critical temperature 50 deg. celsius

Holding at that temp. for a short...

Annealing - Purpose, Process and Effects.

Annealing - Improves softness and ductility in steel and other cold worked metals.

Purpose :

1. To induce softness in steel.

2. To remove strain hardening and increase ductility of cold worked metals.

3. To refine crystal structure.

4. To remove gases from casting.

5. To alter electrical and magnetic properties.

Process:

1. Heating the steel slowly 30 to 50 deg. Celsius...

Gauges - Definition, Types, Principle and other details

Gauges - Gauges are checking instruments and they play an important role in ensuring the limits and tolerances for a given component.

Gauges are broadly classified as :

1. Standard Gauges - Gauge is made as an exact copy of the mating part of the component to be checked.

2. Limit Gauge - These gauges...

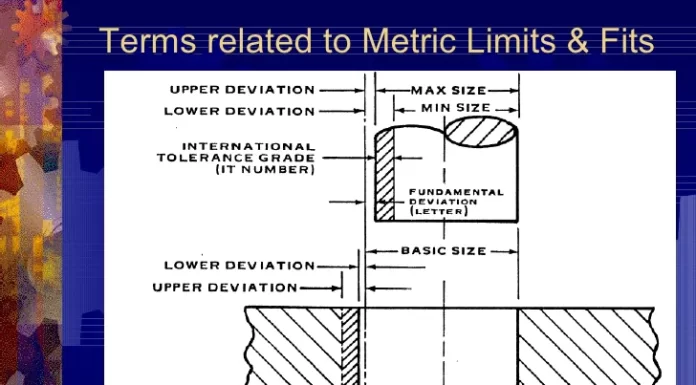

Limits, Fits and Tolerance :

These three words are one of the most confusing words in terms of their definition. One is linked to the other. In all sorts of interview related to Mechanical these words are often asked for. Read this article completely and you will get a clear idea of what are the definitions and differences among these...